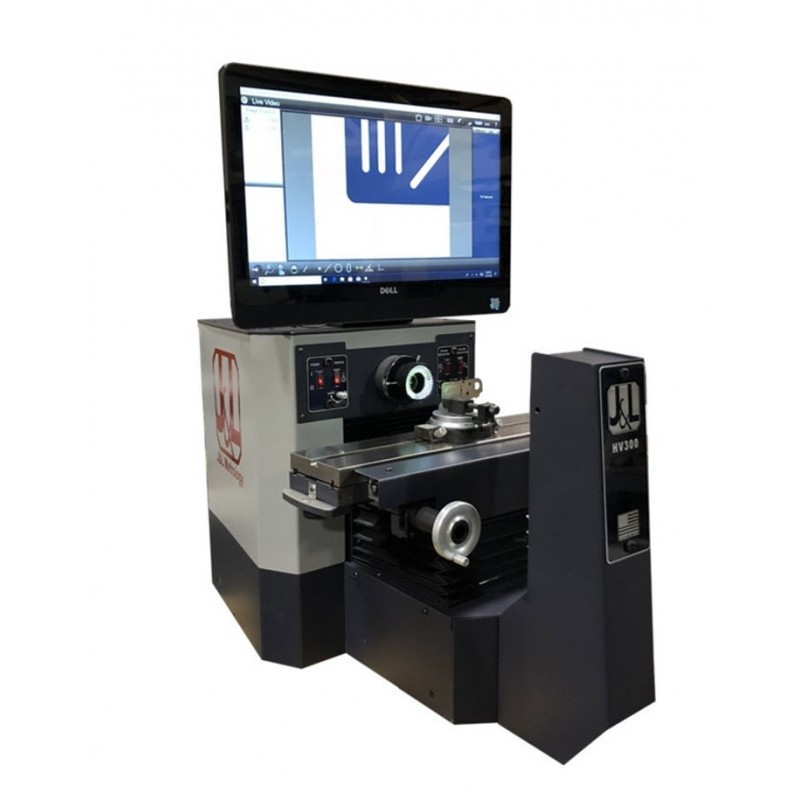

The J&L Epic Vision EVHB-Fixed-M3-CNC2 - Automated Horizontal Video Comparator with M3 Edge Detection Software

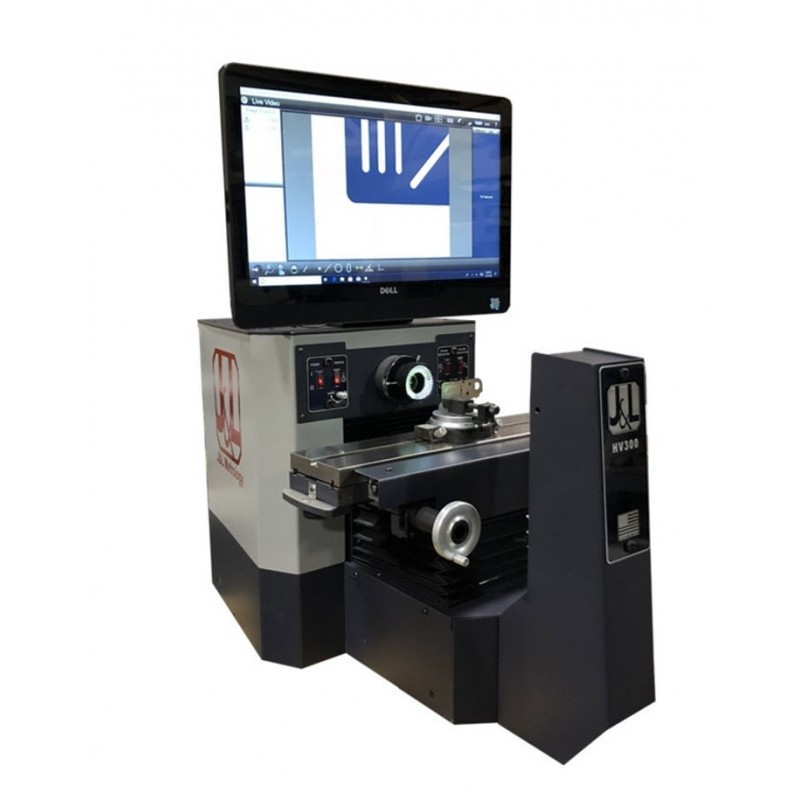

M3 High-Resolution 5MP Digital Camera: Offering fixed or zoom magnification with a Superb Image. The camera provides exceptional clarity for detailed inspections and precise analysis. This range is ideal for both low- and high-magnification tasks in engineering and quality control.

Metlogix M3 Software Integration: The system is equipped with the Metlogix M3 software, which supports seamless measurement workflows. Its advanced edge detection and geometric measurement capabilities, combined with a user-friendly touch interface, make it highly efficient for complex measurements. Engineers can also leverage Part Programs for automatic measurement routines for repeatable tasks.

Powerful On-Screen and Stage-Based Measurement Tools: The system includes integrated software and hardware for accurate on-screen measurements, combined with stage-based movement controls for precise object positioning. and measurement

Motorized 2 Axis Stage for Fast Automatic Measurements -The Motorized 2-Axis Stage enhances the efficiency of measurement workflows by allowing fast automatic measurements. With this feature, engineers can measure a part once, store the measurement program, and then run the same process on multiple parts automatically. The system compares each part's measurements to nominals and tolerances, ensuring consistency and accuracy across batches.

Robust Construction: The system boasts a stable cast iron work surface, ensuring durability and stability for accurate measurements and inspections, even in demanding environments.

Large Measurement Envelope: With a 10" x 6" x 2.5" measurement envelope, the EVHB accommodates a wide variety of parts and components, enhancing its versatility for numerous applications.

High Magnification and Wide Field of View: Designed for the shop floor environment, this system offers a combination of high magnification and a wide field of view, enabling detailed close-up inspections essential for applications that demand both precision and accuracy.

High-Intensity LED Integrated Lighting: The system incorporates integrated high-intensity LED lighting controls, eliminating the need for traditional bulbs. This feature ensures consistent illumination across all working conditions, enhancing visibility without glare or shadows.

Engineers will find the J&L EVHB-FIXED-M3-CNC2 System to be a powerful and versatile tool for high-precision measurements, making it a critical asset in manufacturing, R&D, and quality control environments.

J&L Epic Vision EVHB-Fixed-M3-CNC2,Horizontal Video Comparator with M3 CNC Advanced Edge Detection Softwarel

It's a Comparator. It's an Automated Video Measurement System. It's a 4K Inspection Microscope - All in One!

Introducing the J&L EVHB Fixed-M3 Horizontal Video Comparator - Metlogix M3 Software, the ultimate tool for precision in shop floor optical comparator applications. This cutting-edge system combines the trusted functionality of a traditional comparator with modern 4K imaging technology. With its 4K Smart CamVideo Image, this workstation offers incredible surface detail with seamless image capture and documentation capabilities, providing engineers with a comprehensive solution for inspection and measurement.

Key Features:

M3 High-Resolution 5MP Digital Camera: Offering fixed or zoom magnification with a Superb Image. The camera provides exceptional clarity for detailed inspections and precise analysis. This range is ideal for both low- and high-magnification tasks in engineering and quality control.

Metlogix M3 Software Integration: The system is equipped with the Metlogix M3 software, which supports seamless measurement workflows. Its advanced edge detection and geometric measurement capabilities, combined with a user-friendly touch interface, make it highly efficient for complex measurements. Engineers can also leverage Part Programs for automatic measurement routines for repeatable tasks.

Motorized CNC 2 Axis Stage for Fast Automatic Measurements -The CNC 2-Axis Stage enhances the efficiency of measurement workflows by allowing fast automatic measurements. With this feature, engineers can measure a part once, store the measurement program, and then run the same process on multiple parts automatically. The system compares each part's measurements to nominals and tolerances, ensuring consistency and accuracy across batches.

Powerful On-Screen and Stage-Based Measurement Tools: Integrated software or hardware provides accurate on-screen measurements, while stage-based controls ensure precise object positioning for complex measurement tasks.

High Magnification and Wide Field of View: Designed for the shop floor environment, this system offers a combination of high magnification and a wide field of view, enabling detailed close-up inspections essential for applications that demand both precision and accuracy.

Robust Construction: Built with a stable cast iron work surface, ensuring durability and stability for accurate measurements, even in the most demanding environments.

Large Measurement Envelope: The generous 10" x 6" x 2.5" measurement envelope accommodates a variety of parts and components, making it highly versatile across different applications.

Integrated LED Lighting: High-intensity, adjustable LED lighting eliminates shadows and glare, providing consistent illumination to maintain precise measurement conditions.Backed by a 2-year warranty on mechanical components and a 1-year warranty on electronics, the M3 System is built with high-quality components for long-term reliability, even in the most demanding environments.

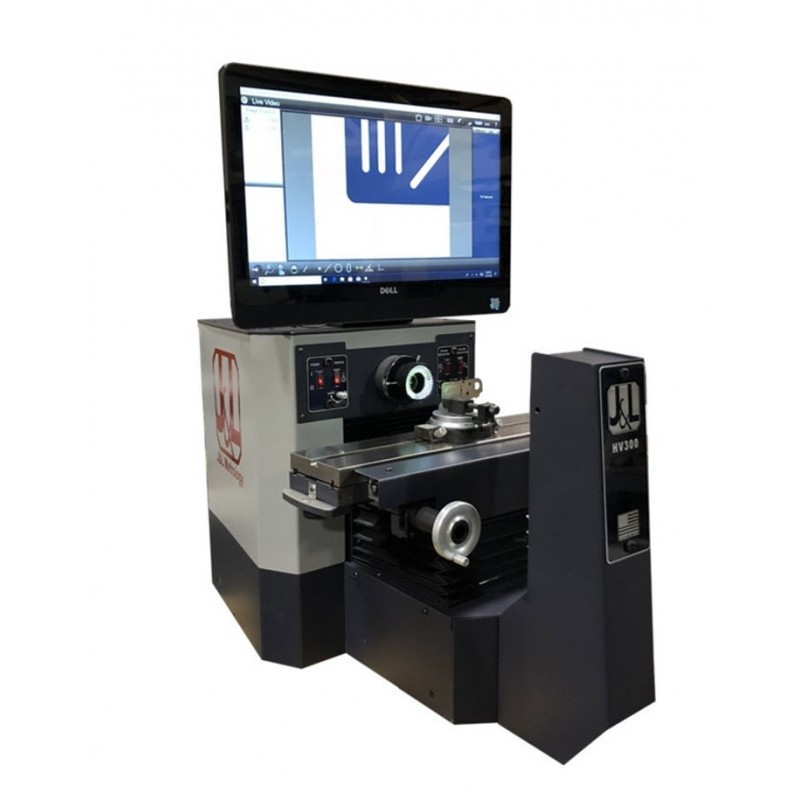

Benefits for Engineers:

Precision and Efficiency: The 4K optics, advanced LED lighting, and precise measurement tools make the G1 Macro System indispensable for engineers who demand accuracy in inspection and measurement tasks.

Versatility in Application: Whether in R&D, manufacturing, or fieldwork, the M3 touch Screen design and integrated tools make it adaptable to a wide range of engineering tasks, without the bulk of traditional equipment.

Special Announcement

Scienscope Internation and J&L Metrology have entered into an exclusive sales and marketing agreement as of March 1, 2021. Both companies have combined their strength in optical technology, manufacturing capability, and worldwide distribution/support for metrology based video measurement systems.

Benefits

Scienscope International is established as a leading developer in optical/video technology and X-Ray inspection systems. J&L Metrology has been in business for over 100 years and is well known as the leading international manufacturer of optical comparators, digital readouts/software systems, and stage-based video measurement systems.

Quotes and Purchase

All systems will be quoted and processed by J&L Metrology.

For inqueries, please contact:

J&L Metrology

280 Clinton Street

Springfield, VT 05156

https://www.jlvideosystems.com

Metrology Sales: 203-494-5082